Fenix Automation muut tuotteet.

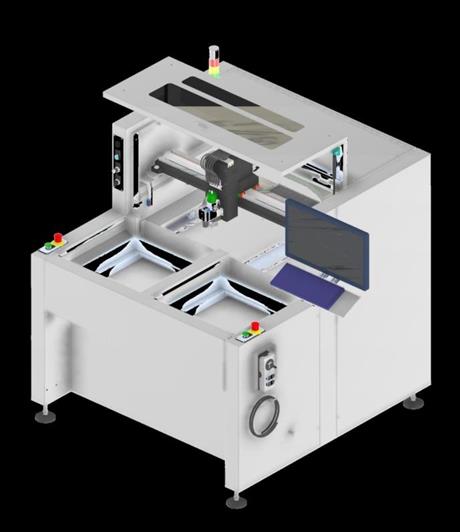

Test handler NH-00

Inline functional test with automatic loading and unloading of specific products or PCB

• R to L or L to R flow direction

• Pass through function

• User interface by touch screen

• In out safety shutters

• Interchangeable upper and lower fixture

• Space for test system / instrument integration

• In Line Capability

• Returning Conveyor

• Servo Driven Press

• Camera Inspection

• LED Verification

• Trimmer Adjustment and Switching

• Code Reading

• Traceability Environment Compliant

Technical Features

- In – Out SMEMA Interface

- ESD Safety Design

- CE Compliance

- Flat Belt (carrying edge 3 mm)

- Power Supply - 230Vac 50/Hz 16A

- Std. conveyor speed 12 m/min

- Electric Width Adjustment (EWA)

- Press force up to 2500N

- Weight 400 kg

PCB specification

- Max/Min PCB width 500 mm/100 mm

- Max /Min PCB length 400mm/100 mm

In-line depaneling cell RA-00

• Suitable for medium and high volume production

• New product setup < 3 minutes

• Camera for manual teaching

• Cutting route importable from DXF files

• Compact foot print

• Upper robot suitable for pallet loading

Technical Features

- Line length 1000 mm

- In – Out SMEMA Interface

- Semi-automatic specific product gripper change system

- Continuous bit inspection

- Automatic bit changing system

- ESD Safety Design

- Ionized working environment

- Direct import of routing programs from .dxf files

- CE Certification

- PCB Conveyor:

a. Flat belt (3 mm carrying edge)

b. Std speed 12 m/min

c. Electric Width Adjustment (EWA)

- Flat belt outfeed conveyor for de-paneled boards

- Embedded dust suction pipe (PCB bottom side)

- Automatic scrap material evacuation

- Power Supply - 230Vac 50/Hz 16A

- Weight 1.300 kg

PCB specification

- Max/Min PCB width 400 mm/100 mm

- Max /Min PCB length 450mm/100 mm

Options

- Specific product gripper

- External dust extractor

Standalone depaneling cell RA-50

Standalone depaneling cell

• Suitable for high mix production

• New product setup < 3 minutes

• Cutting route importable from DXF files

• Hand pendant for manual teaching

• Compact foot print

• Double fixture shuttle for loading time optimization

• Loading / Unloading area protected by optical barrier

Technical Features

- Standalone configuration

- Double shuttle

- Continuous bit inspection

- Manual bit changing system

- Embedded dust suction pipe (PCB bottom side)

- Easy product fixture replacement

- ESD Safety Design

- Ionized working environment

- Direct import of routing programs from .dxf files

- CE Certification

- Power Supply - 230Vac 50/Hz 16A

- Weight 400 kg

PCB specification

- Max/Min PCB width 400 mm/100 mm

- Max /Min PCB length 450mm/100 mm

Options

- Specific product fixtures

- External dust extractor

- Automatic bit change system